Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: MPI

Whether CNC Machining: Cnc Machining

Packaging: Carton

Productivity: 3000 Piece/Pieces per Month

Transportation: Land,Air,Ocean

Place of Origin: Taiwan, China

Supply Ability: 3000 Piece/Pieces per Month Will vary from item to item

Certificate: ISO90001

Port: Keelung,Kaoshung

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CIF,EXW

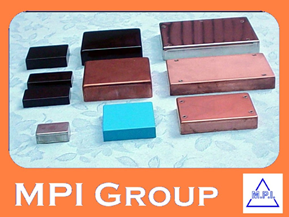

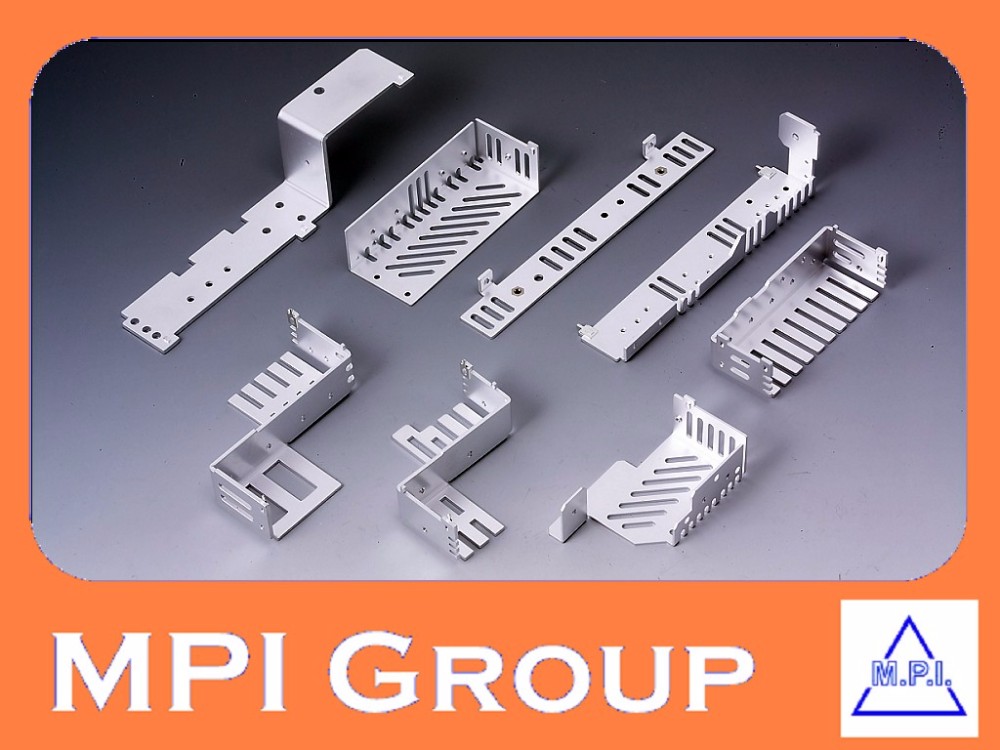

Custom OEM Power Case Sheet Metal Fabrication

Sheet Metal Fabrication Description

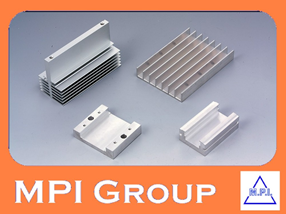

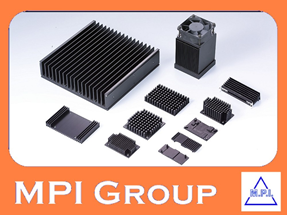

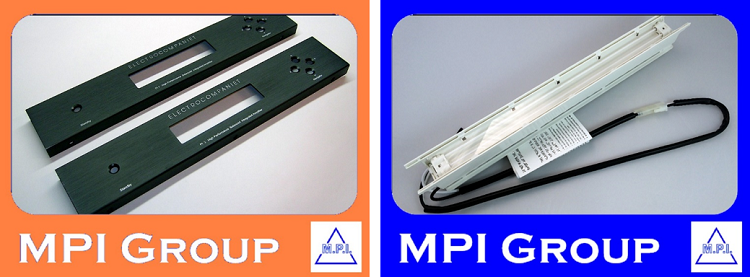

Extrusion aluminum Heat Sink is used to dissipate heat from electronic components to the surrounding environment. The specification of extrusion aluminum heat sink includes the following:

1. Material: Extrusion aluminum heat sinks are made of high-quality aluminum alloy. The most commonly used aluminum alloys are 6061 and 6063.

2. Dimensions: The dimensions of the heat sink depend on the application and the size of the electronic component it is intended to cool. The length, width, and height of the heat sink are important factors to consider.

3. Fin density: The number of fins per inch on the heat sink determines its cooling capacity. The higher the fin density, the better the heat dissipation.

4. Fin thickness: The thickness of the fins affects the overall weight of the heat sink. Thicker fins provide better cooling but add to the weight of the heat sink.

5. Base thickness: The thickness of the base of the heat sink affects its rigidity and ability to transfer heat from the electronic component to the fins.

6. Surface treatment: The surface of the heat sink can be treated with anodizing, powder coating, or other methods to improve its durability and corrosion resistance.

7. Mounting method: The heat sink can be mounted using clips, screws, or thermal adhesive. The mounting method should be chosen based on the application and the weight of the heat sink.

8. Thermal performance: The thermal performance of the heat sink is measured in terms of its thermal resistance and thermal conductivity. The lower the thermal resistance and the higher the thermal conductivity, the better the heat dissipation.

Custom Heatsink Display:

|  |

|  |

|  |

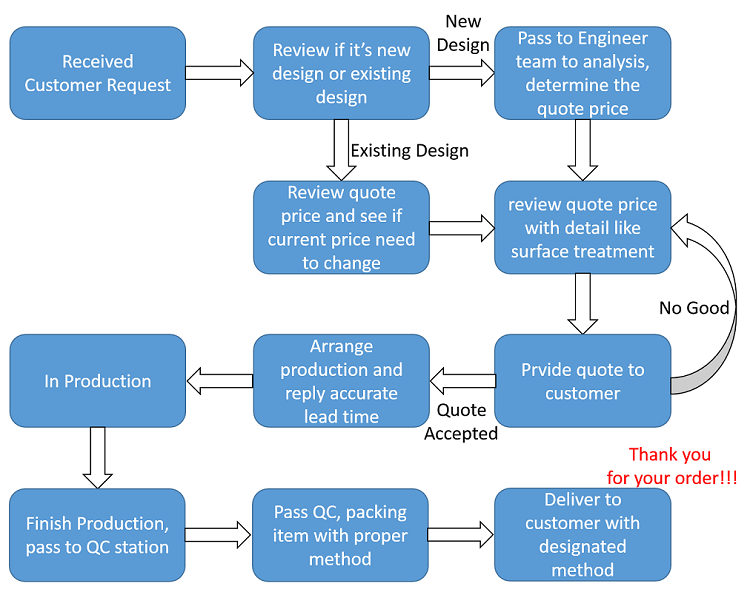

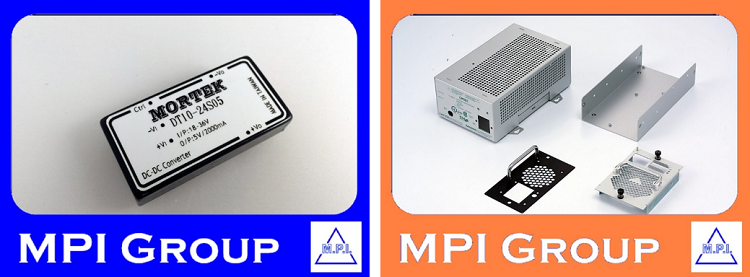

Metal stamping is the professional region of MPI which have over 20 years of experience in this fielded. MPI help customer build their desired products with dedicate technic. From the heat sink to switching power case and amplifier case, we are capable to finish variety of metal request. Quality team help eliminate the chance that customer receive defeat products.

MPI have stamping machine 40t, 80t 100t and up to 200t along with bending machine and NCT machine; CNC machine. By those machines we are able to finish most of the request from customer without the need of outsourcing.

MPI's business partner such like Linear, SL power, Murata…etc. for more than 20 years till now, which means MPI is the company that customer can trust and work with.

We provide packaging service with double-wall carton and proper stuff to protect your item. Depends on different quantity we can provide pallet service. Both wood pallet and paper pallet is available. Pallet will be sealed and protected by L-shape protector to make sure item safe.

We help customer deliver in different ways, depends on the goods and customer need. From Air Cargo to Sea shipment, Express to forwarder, we can provide various shipping method for you!

MPI have two division, electronics design & assembly house and metal stamping & CNC chop.

In Electronics shop we provide our professional skills on power electronics design and manufacture. From A to Z, we can help you translate your idea into real products.

Our Metal shop provide professional stamping service which include creating mold, stamping and surface treatment. The implementation of CNC machine provide high Precision Machining Parts and machining service to our customer.

Over 20 years experience on doing business with US and EU customers. We can understand what you need and what you concern.

We are able to reply to customer within 24 hours, which can let you speed up your decision and solve your problem immediately.

|  |

Product Categories : Sheet Metal Fabrication > Heat Sink

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.